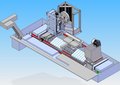

FWN300-4A Milling and Centering Machine

FWN-300-4A machining tool is a state-of-art CNC operated piece of equipment, which design was based on the innovative machining technology developed by ASCO in cooperation with SANDVIK - an international market leader in production of cutting and forming tools.

Its design allows to machine both ends of a railway axis, whilst dividing the process of machining into stages, thanks to the use of a CNC operated rotary table that significantly shortens the technological process.

From the perspective of the rotary table, on one side there is a headstock with a stationary spindle, fitted with a machining tool for efficient cylindrical axis endings machining. The working range of the headstock is only alongside the machine bed, which, in combination with its high power and torque provides great stability of the machine and efficiency of the machining process. In addition, it is possible to fit other tools in the headstock which increases the versatility of the machining tool even further.

On the other side of the machine, there is a smaller headstock controlled in three axes with a tool magazine, allowing to perform any machining operations that require less power and more technological versatility.

On the other side of the machine, there is a smaller headstock controlled in three axes with a tool magazine, allowing to perform any machining operations that require less power and more technological versatility.

The identical shape of the axle ends by the end of a machining cycle is guaranteed by the rotary table, on which the processed object is mounted.